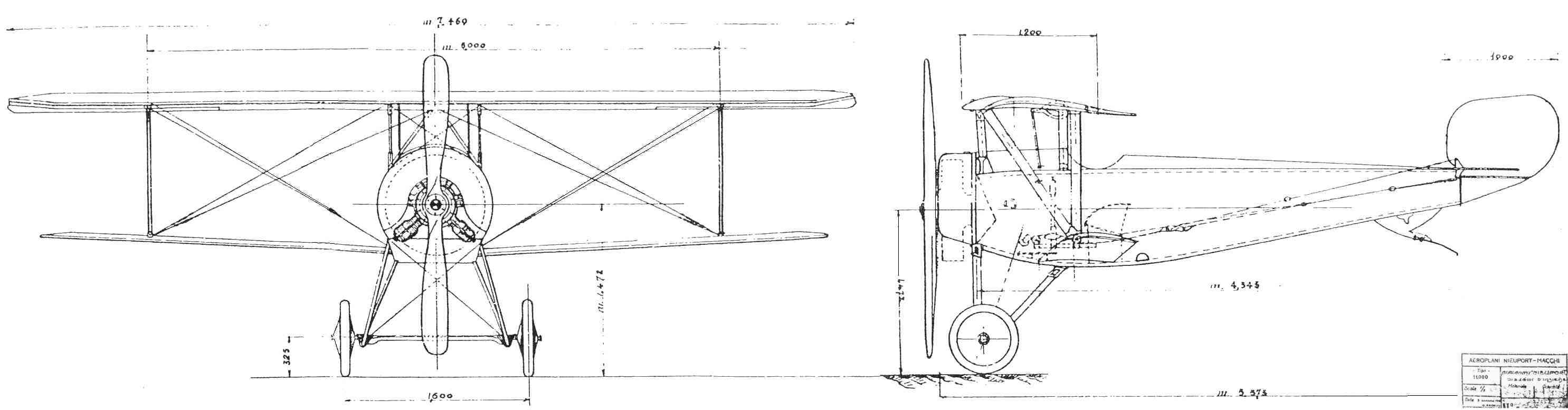

• Building a Nieuport 11 replica •

The Nieuport is a sesquiplane - the lower wings are about half the area of the upper wings. They have a single spar and are mounted with 5 degrees of dihedral. The wings are swept back by 6 degrees and have curved tips and so construction is not straightforward.

The first stage was to produce the wing ribs.

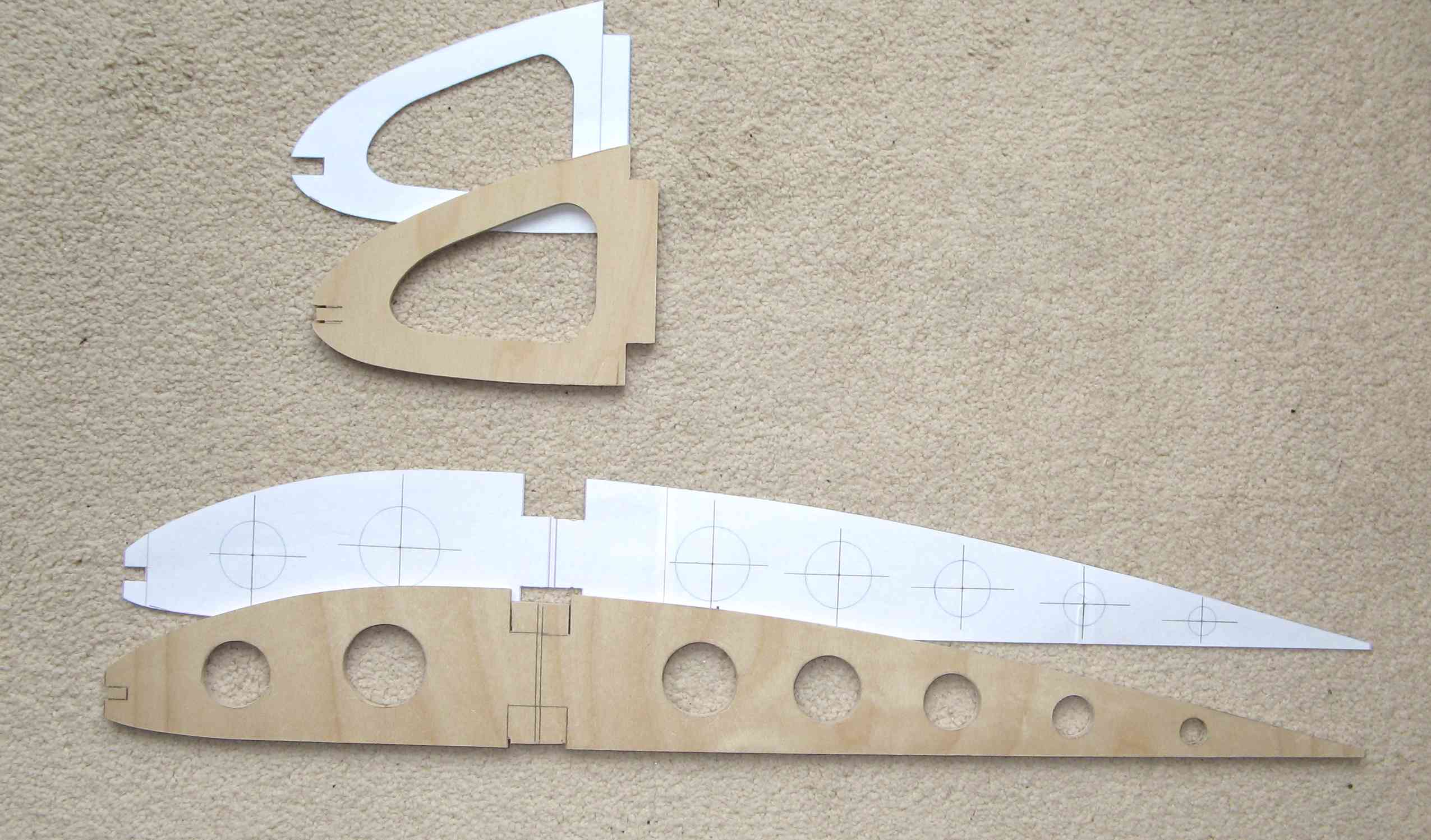

The lower wing ribs are made from 1/4" birch ply as are the main wing nose ribs.

Paper patterns were made from the original plans and 1/8" templates cut with a jigsaw and carefully finished on a sander.

Blanks from 1/4" ply were cut out using a jigsaw, each slightly larger than the final size.

The blanks were nailed to the template in turn, the nails going through a part of the rib that would be subsequently trimmed off.

The ribs were then produced using a template cutter on a router.

The main wing nose ribs were produced at the same time using the same process.

To save weight I decided to alternate between 1/4" and 1/8" thick ribs, 2 wider ribs to each thinner one.

The wing spars for upper and lower wings were made at the same time.

Each spar comprised a 1/8" birch ply web with two 1/2" x 3/4" spruce capstrips top and bottom.

The spars were reinforced for fittings and at the root end and other attachment points with wooden spacers and ply covers.

Holes for the fittings were pre-drilled before assembly, using the actual fittings as guides.

The wingtip was laminated from 1/8" x 3/4" spruce strips.

The pieces were steam bent for about 15 minutes and clamped in a jig for several days.

The individual pieces were then separated and given several further days to dry out.

The laminations were then glued using Aerolite adhesive.

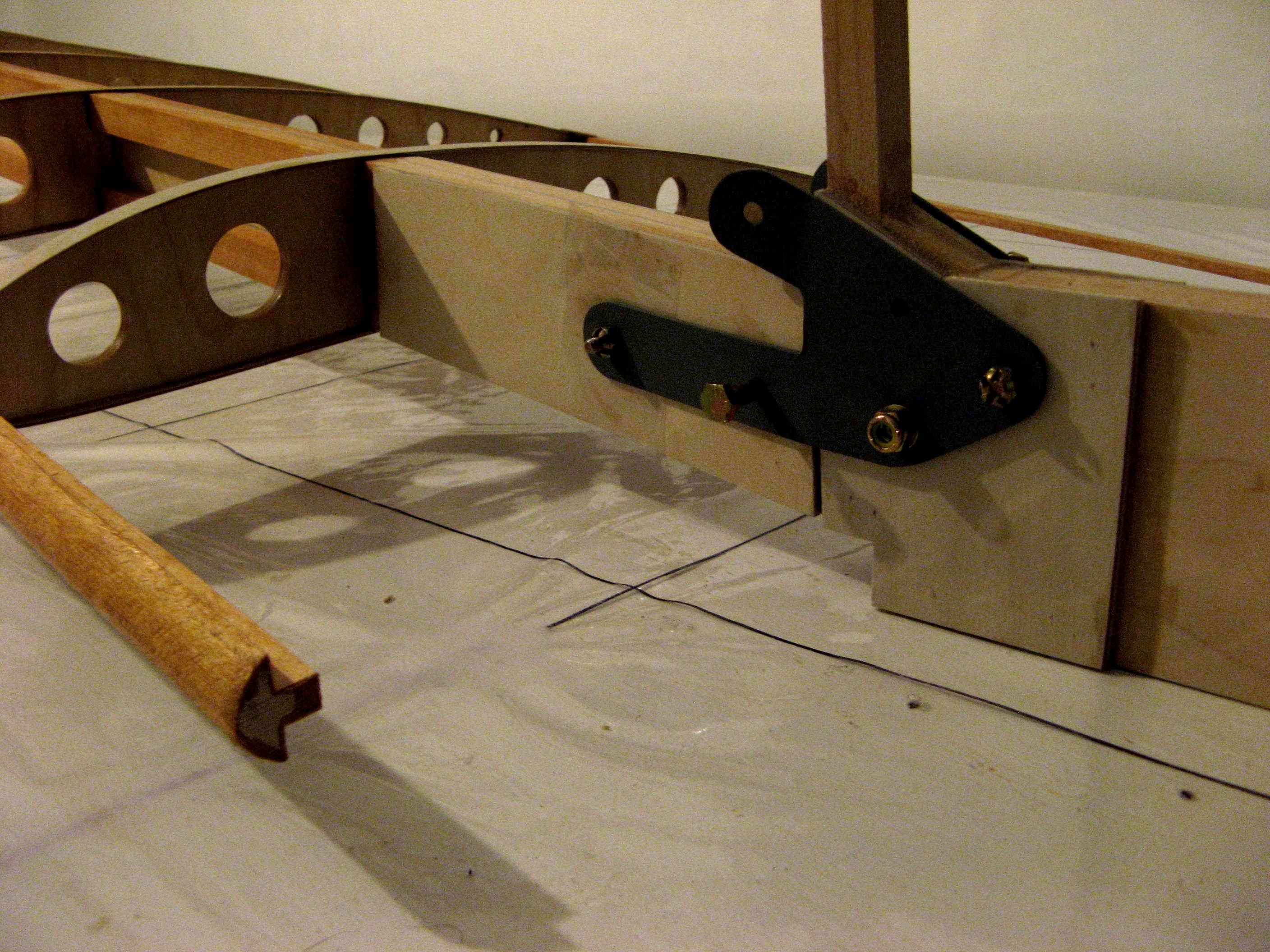

A 12 foot long table was built and carefully levelled.

The table was painted matt white and plastic sheet laid over (epoxy does not stick to plastic).

Layout lines were then drawn using a permanent marker from dimensions on the plan.

After construction of the first wing the plastic would be flipped over to create a mirror image in order to build the second wing.

Wooden blocks and cams were screwed to the table to hold components during assembly.

The final wing after 1/2" capstrips were added to the top and bottom of each rib, but before sanding the leading and trailing edges, and wingtip.

The capstrips add strength and also provide extra area to attach the fabric to the ribs.

Attachment fittings were fabricated from .09" 4130N steel

These had to account for the 6 degree sweep back and 5 degree dihedral.

The fittings incorporated tangs for the lift wires.

The holes in the wing spars were drilled oversize and steel bushings expoxied in place so that the wing bolts could be removed for detachment of the wings.

Without the bushings regular removal of the wings would cause the holes in the wood to enlarge.